Each 9.99 dollar top bought at Forever21 or H&M contributes to the three trillion-dollar industry known as fast fashion. These brands attempt to capture all of the latest fashion trends by quickly and cheaply manufacturing clothing — taking an item from the design process to the stores in just a few weeks.

For the first time in history, consumers are able to walk into a store and find a stylish dress for ten dollars or a sweater for seven dollars. Nabila Ghilzai, who has worked in the fashion industry for almost thirty years at companies including Byer California and Vince, compared the process of buying fast fashion clothing to a trip to the dollar store.

Photo by Sofia Morris

“If you go to the dollar store, you buy things you don’t need. You think to yourself, ‘I only spent a dollar’ and then you will throw it away and not feel bad about it. But, if you spend three hundred dollars on an item you will be more picky about that item and take better care of it,” Ghilzai said.

The rapid evolution of the fashion industry has left companies and consumers alike wondering how the desire for clothing became an industry that according to Fair Fashion Center, employs one in every six people and fuels the growing problem of climate change.

The fast fashion industry has grown with time to fit the needs and desires of the consumers. Before the Industrial Revolution, all clothing was bespoke. People who did not have the means to have custom made clothing shopped at “slop shops.” These shops — equivalent to second hand shops today—were frequented by the middle to low-income population. “Slop shops” resulted in a demand for ready-made, cheap clothing that was accessible to all people. During the Industrial Revolution, new technology such as the water frame, spinning mule, sewing machine, and cotton gin aided in the mass production of clothing.

At this time in the United States, the cotton industry was thriving. Cotton was picked by slaves and sold cheaply and in large quantities to Britain for the production of goods, including clothing. The combination of new technology and the excess amounts of cotton were the catalysts for the shift away from bespoke clothing to mass-produced clothing.

Before World War II, most everybody in the United States bought their clothing at general stores. The general stores had two to four seasons per year and produced their clothing with a focus on cost rather than demand.

“People wanted cheaper garments, so the fabric quality had to go down. From using two to three dollar fabrics they went to using one dollar fabric,” Ghilzai said.

At the start of WWII, the United States needed large quantities of garments to be produced at low price points. The production of the garments shifted to large manufacturers and the production was outsourced abroad, where labor was cheaper. Retailers that continued to manufacture domestically lost customers and went out of business because they were unable to compete with the outsourced labor prices. By the 1980s, the majority of all fashion production had moved from the United States to overseas.

Now only three percent of clothing is manufactured in the US, according to the American Apparel and Footwear Association, and most of those items are high-end specialty garments.

With the emergence of the fast fashion industry, people are able to spend a lot less money on their clothing. According to a 2003 report conducted by the Bureau of Labor Statistics, four percent of the average American’s annual income goes towards fashion compared to 12 percent in the 1950s.

The rise of cheap commodities has become so integral to American consumerism that shoppers aren’t necessarily looking for a specific item, but instead, searching for deals, as a joint study at Stanford, MIT, and Carnegie Mellon found. “There are some brands where it is all about price and they do not feel a need to change their businesses because their customer isn’t telling them they should,” Nicole Bassett said, co-founder of the Renewal Workshop, a non-profit which upcycles discarded apparel and resells it at a lower price. Pulled in by low prices, trendy styles, and flashy advertising strategies, shoppers are now purchasing four times the amount of clothing they did 20 years ago.

But are they really wearing this clothing? A recent Weight Watchers survey conducted in the United Kingdom suggests not, as participants reported that they had an average of 227 dollars worth of unworn clothing in their closets. As prices lower, fashion is becoming worth less and less to the average customer and eventually ends up in a landfill.

The three trillion dollar fashion industry is the second largest polluter in the world, making up 10 percent of global carbon emissions. The fast-growing fast fashion industry is at the root of this problem. According to a 2013 report by fashion brand Zady, the fashion industry manufactured 150 billion new garments in 2010. For all those clothes to be bought, every person in the world would have to buy about twenty garments per year. The breadth of the industry and the number of garments produced each year is only increasing.

And the more clothing bought means more thrown away. The Environmental Protection Agency (EPA) reported in 2014 that consumers discarded an average of 68 pounds of textile waste into landfills per person per year, adding up to whopping 16.2 million tons of textile waste per year. “If you buy something that’s cheap and disposable, then that is the world you are investing in” says Basset.

The process used to make the clothing cheaply and efficiently is deeply damaging to the planet. Over half of clothing is made out of synthetic materials originating from plastic, the production of which uses large amounts of energy and emits dangerous byproducts typically released into wastewater. Overseas countries where the clothing is being produced use coal power in their factories. The combustion of coal releases dangerous chemicals such as sulfur dioxide, nitrogen oxide, and carbon dioxide that lead to acid rain, respiratory illnesses, and smog.

Another huge problem is microfibers the tiny threads shed from synthetic fabrics. Researchers at the University of California at Santa Barbara found that, on average, synthetic fleece jackets release 1.7 grams of microfibers each wash, but microfibers are not only released during the wash. They are also released during daily wear. Microfibers are easily consumed by the wildlife in the oceans and makeup 85 percent of the human-made debris on shorelines according to a paper written by Mark Browne, a researcher at the University of New South Wales, Australia. One may not realize while shopping, but each item that is produced worsens global warming and the disintegration of the planet.

The movement of the clothing factories overseas makes it difficult to maintain ethical and humane working conditions. The fast fashion industry is notorious for its unsafe working conditions and disregard for its workers’ rights. The majority of people working in the fashion industry work in factories overseas in the production stage of the garments. They are paid minimum wage, which is often exponentially lower than a living wage. UNICEF and the International Labor Organization estimate 170 million children work in the clothing industry all over the world. Though child labor is illegal, factories are rarely inspected, allowing employees to lie about their ages. The lack of inspection also leads to sexual and physical abuse against women in the factories. More than 540 workers at factories in Bangladesh, India, Cambodia, Sri Lanka, and Indonesia that supply the retailers of Gap and H&M have described incidents of threats and abuse, according to two separate reports published in May of 2018 by Global Labour Justice. Reports of physical, sexual, and verbal abuse are common in Walmart’s factories as well. Many workers fear reporting these incidents, believing they will lose their jobs or face more abuse as backlash.

With the majority of fashion companies licensing production to factories as opposed to owning their own, the companies are able to avoid taking responsibility for the dangerous conditions in their factories. When companies are exposed for mistreating their workers, the public is usually enraged for several days, but soon accepts the company’s apology and continues buying the companies clothing, even though the conditions in the factories remain the same. The working conditions in the factories are detrimental to the worker’s health. Due to the lack of ventilation in factories and long working hours with no breaks, garment workers in many factories that produce for Walmart report various illnesses associated with their working conditions. The factories are unequipped with basic safety resources such as first aid kits, fire extinguishers, fire alarms, and emergency drills. In November of 2012, a fire started in a factory in Bangladesh that produced garments for American retail companies such as Walmart. The workers were locked in and attempted to break the bars off the windows to escape the heavy smoke, but were largely unsuccessful. Those who were successful had to jump out of the multi-story building in an attempt to escape the fire. 117 people died and more than 200 people were injured. Less than a year later, on April 13, 2013, the eight-story Rana Plaza building in Bangladesh collapsed, leaving 1,100 people dead and thousands more injured. The building, which housed factories for North American and European garment companies, collapsed due to bad infrastructure.

Despite the tragic realities of the industry, the average consumer in a wealthy country is so geographically and psychologically distant from fast fashion’s negative effects that buying a piece of clothing seems practically inconsequential. With the ever-increasing trend turnover rate, buyers feel that they must have what’s popular, a desire that is only encouraged by the instant gratification of online shopping, quick deliveries, and low prices.

Fast fashion is fueled by social media and the consumer’s desire for affordable clothing.

“A young girl buys something, takes a picture, and posts it on Instagram. Now she doesn’t want it for her second picture, but she doesn’t have enough money. She goes to Forever21 and buys a new trendy garment and throws the old one away. It is a vicious cycle,” Ghilzai explained.

A UK Censuswide survey found that 1 in 10 people discard a piece of clothing after being photographed in it online three times.

We surveyed the Lick community to get a sense of what students have to say about fast fashion. A number of students value price over all else. “Especially recently, I have thought of [the environmental and labor impacts of fast fashion] but it is kind of hard when the allure of cheap clothing is so strong,” Laura Boyd ’20 said.

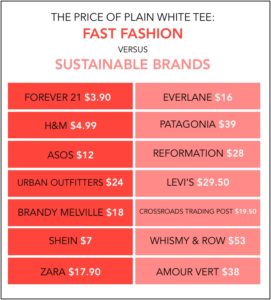

Graphic by Rafi Donohoe and Sofia Morris

When asked about the environmental and humanitarian implications of the fashion industry, students responded that they are conscious of these factors, but they don’t affect their purchases. “A lot of the time it’s hard if you’re on a budget to shop at [sustainable clothing stores] that take [the environment and labor] into account because since they are paying their workers more they have to charge you more, and that’s hard if you are a student and you don’t have a lot of money,” Oona Fitzpatrick ’19 said.

Some value quality and the lifetime of their clothing, such as Joni Lee ’19, who says that “Is the quality of [an item] worth the price you are paying? My philosophy is that if you’re going to be buying something you might as well buy something that is nice so it will last a long time.” Alice Norrell ’21 boycotts the fast fashion industry by shopping second hand. The power to change the fast fashion industry lies in the hands of the consumer. In the age of social media, a small yet vocal group of influencers are speaking out against fast fashion and are shedding a light on the realities of the industry. In an attempt to combat the danger of the fast fashion industry, a new cohort of labels and brands have emerged and are re-popularizing the idea of “slow fashion.” Brands such as Patagonia and Everlane are now marketing how they source sustainable materials, and even notoriously inhumane fast fashion brand H&M responded to customer’s interest in the environment by introducing a line of clothing made from recycled materials.

“[Shoppers] should think about [fast fashion] as I hope they are thinking about every other raw resource we are using on planet earth … every new thing you get costs the earth,” said Sarah Sands, a veteran of the fashion industry who has worked at Levi’s and Gap. Fast fashion is a complex, international industry — and one that relies on the consumers. As the awareness grows, many shoppers have the power to vote with their wallets by purchasing sustainably and secondhand.