Origination of the Tech Arts program

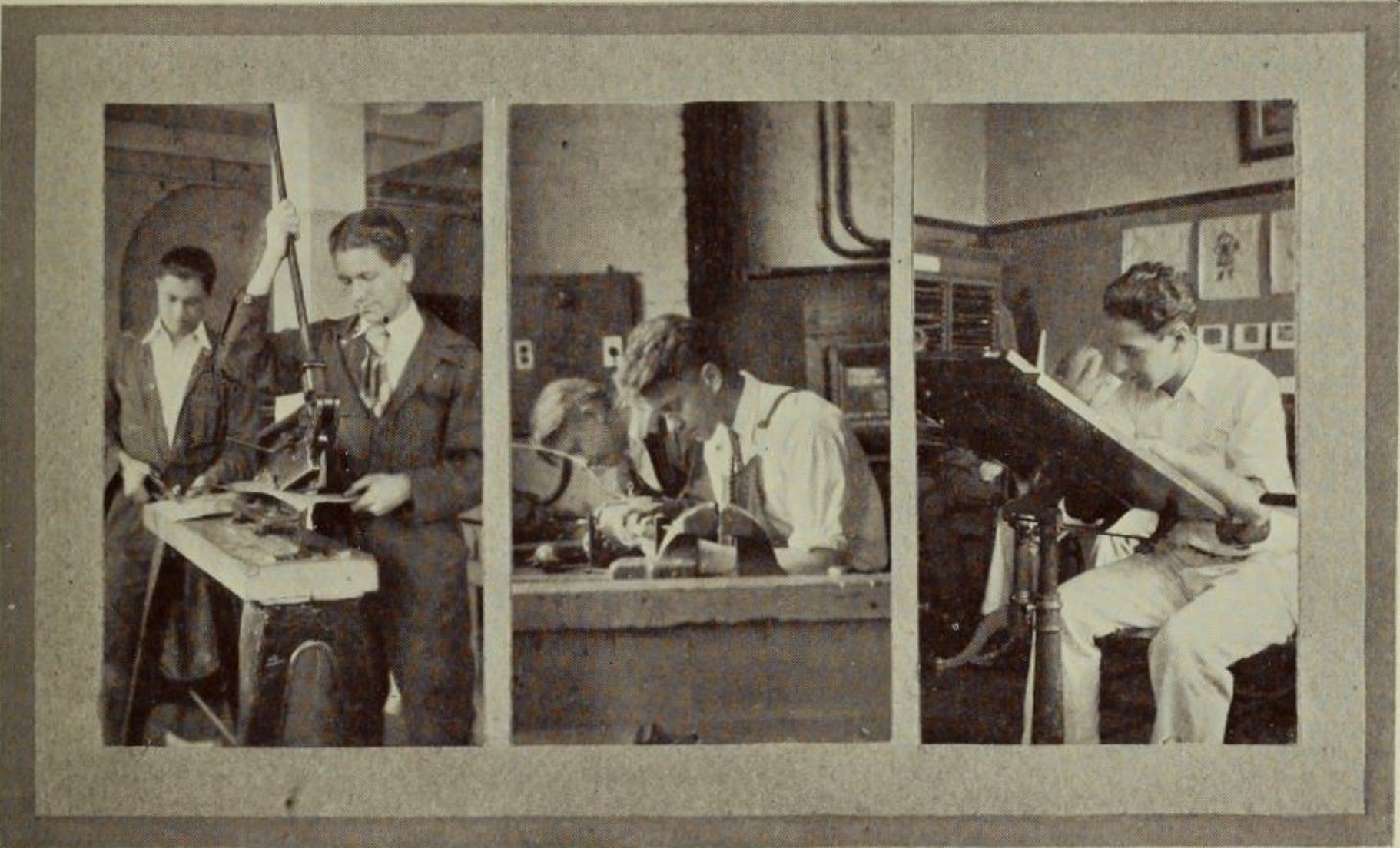

Courtesy of the LWHS Archives

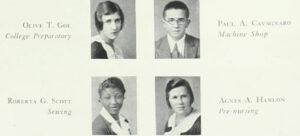

Endowed with a $400,000 bequest by Jellis Clute Wilmerding (1833-1894), the Regents of the University of California founded the Wilmerding School of Industrial Arts, which began operations in buildings located next to the California School of Mechanical Arts — also called the Lick School, after James Lick (1796-1876). Both institutions valued technical expertise. These two schools collaborated closely over the years, and with the Lux School for Industrial Training for Girls, formed a trio of schools that shared facilities and focused on technical arts as well as academic education.

“The shops of the Lick-Wilmerding Schools, which have been in operation for the past twenty-four years, have gained an enviable reputation for the thorough mechanical training which they afford the students. The work is theoretical, as well as practical, and every student has the privilege of choosing the particular branch of shop work in which he is especially interested after he has completed the regular prescribed course that every student must take during his first two years.”

L.W. L Life Commencement – May, 1918

The L. W. L. — short for the Lick – Wilmerding – Lux magazine, illustrates the technical work and skills that now-defunct L. W. L. shops classes primarily consisted of more than a century ago.

Mechanical Drawing

The mechanical arts curriculum includes coursework that may incite familiarity for current LWHS freshmen — mechanical drawing. The magazine emphasizes a gradual build-up from introductory courses to more advanced mechanical drawing that “starts in the first year, but it is not until the end of the third year that the student is given actual machine drawing” and that this more “advanced work given in the third year leads up to the final work in the Senior year.”

The L. W. L. mechanical drawing department, described as “one of the busiest [departments] in the school,” involves designing a plethora of devices: pumps, steam turbines, and engines are a few examples. Below is an excerpt from a December 1918 edition of the L. W. L. magazine that details student work:

“Fritz” Schubert is designing a centrifugal pump and is progressing rapidly. “Barney” Dolan, the other apprentice of the ’18 X class, hopes to complete a 30- foot tug boat this term.

The Senior class is the proud possessor of a great “mechanical four” — Kraut, Englebret, Hansen, and Casto. Kraut and Englebret are designing a 100 H. P. steam turbine. Both claim to be the “chief consulting engineer,” and when not draughting they spend the time debating the question. Hansen and Casto are constructing a 1 5 H. P., two-cylinder marine engine.

The other Senior apprentices are trying to keep up to the standard set by the “regulars.” “Jerry” Keefe is designing a guard for the school’s steam whistle; Ben Franklin is well started on a hoisting hook, while Scott is working over the details of a 6 H. P. motor. Tosi and Ritchie divide the time between drawing and gazing out of the window.’

During senior year, actual design and computation of various machines were taught, and through the mechanical drawing department, pumps, motors, hoists, steam and gas engines, etc., were accurately calculated and designed — later to be made and assembled in the shops.

Electrical Shop

Much like L.W. L.’s other shops, the electrical shop of the early 20th century primarily prioritized practicality in hopes of preparing students to be “regular electricians.”

“Hobson and Hildebrand, with aid of “Paddy” Walton, are tracing conduits. Scott is making a transformer and hopes it will live up to his expectations.”

The electrical shop bears similarity to the LWHS circuits and electronics shop of today — circuits were utilized in devices like bells and phones, very much in the nature of current courses like “Analog and Digital.”

Patterning Shop

In the patterns shop, patterns for the machines designed in the mechanical drawing department are made.

“The patterning shop is well equipped with a large assortment of lathes, band saws, jointers, planers, etc., besides a large assortment of working tools.”

After the patterns are completed they are turned over to the foundry, where all castings for the machine shop are poured. The various patterning castings include lathes, motors, gas engines and sets for steam hoists. Upon receipt of the castings from the foundry, the machine shop immediately commences on the final stage of construction.

Forge Shop

In the forge shop, all lathe tools and equipment for lathes are made. All tools used in the shop itself have been made by the students, and many tools were sold outside of the school — proving the merit of their work.

Automobile Shop

The automobile shop, which is one of the latest additions, has proven very successful. A large number of students have brought their machines there for overhauling. A number of motor bobs have been built here during the past six months.

Cabinet Shop

The cabinet shop worked on various pieces of furniture — with its primary goal being to provide the University of California with chairs, desks, and cabinets. Besides a number of small jobs in furniture, a significant amount of cabinet work was completed for the University of California.

Students claimed the “impressive reputation which has been gained by Lick and Wilmerding along the technical and industrial lines” as only possible because of “the untiring work of the respective instructors.”

World War 1 and Military Exchange with Tech Arts

“Soon we shall be scattered to all parts of the earth; the God of War will claim his share of us, but always we will be bound together by the ties of friendship formed at school, and we will keep in touch with school affairs thru the medium of the Alumni. The world keeps moving and it is decreed that we shall move on and make room for others, but it is difficult to leave the friends we have made, and our memory still clings to the happy days we spent at Lick-Wilmerding and Lux. But the best of friends must part some time; so, goodbye Lick-Wilmerding and Lux, and the best of luck to Nineteen Nineteen in their Senior year!!”

During the months of July and August 1917, Lick-Wilmerding had a contingent of 140 drafted men under mechanical training in various shops. The top floor of the LWHS’s new shops building made ideal barracks while the second floor was occupied by the officers’ quarters. At mess call (a military bugle call), the men assembled in the old Wilmerding electrical shop where “good, wholesome ‘chow’ was served.” To work in practice at “the pick and shovel art,” the recruits squared up the Wilmerding oval and made the famous old cinder path actually look “like something.” Many soldiers found nearby Jackson Park an ideal parade ground where the men “shouldered arms” and stamped around in marching formations.

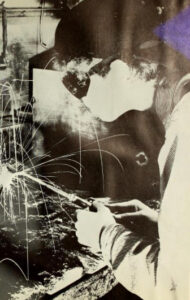

Development of Electric + Wood Shops

The introduction of the electric and wood shops was not an institutionalized building process, but instead student-led. In 1914, Students built an electric shop from scratch, including the wiring that made up the room, while hand-cut wood beams, planks, and sheet metal composed the student-built woodshop. Students also were heavily involved in the development of new buildings on campus, noting in 1920 that “the carpentry, plumbing and sheet metal departments have all been working on the new building during the past year, and it will be only a short time before they complete their task.”

1991 Renovation (Architecture + More)

A commencement quote about the reputation of the Shops from LWL Life in 1917:

“The Lick-Wilmerding School has gained a statewide, if not a nationwide, reputation for its mechanical and educational achievements, and this reputation is upheld by the stream of men it turns out into the field year by year. We seem to have the advantage over the majority of schools in our shop work. This fact can only be attributed to the thorough and methodical method of teaching the elementary branches of mechanics from the freshman to the senior year.”

—LWL Life, Commencement, 1917